IVP Limited: Driving Growth Through Innovation and Excellence

IVP Limited, founded in 1929, is a listed company and an integral part of the Allana Group. Originally associated with the Tata Group and later acquired by the Allana Group, IVP expanded into other industries. It all began in the vegetable oil industry, and it holds the distinction of being the first Indian company to manufacture Foundry Chemicals. IVP can produce approximately 50,000 tonnes annually between its Tarapur and Bangalore manufacturing facilities. Catering to industries such as PU Systems for footwear, adhesives for flexible packaging industry, foundry chemicals, coatings, composites, refractory, powder, and insulation resin. IVP Limited supports the expansion and prosperity of the Allana Group and its clients as a reputable participant in these markets.

- With a rich history, IVP combines tradition with modern advancements.

- Our company is dedicated to enhancing value by offering a variety of chemicals, striving to exceed customer expectations through tailored solutions.

- IVP's market success is fueled by its knowledge and commitment to its customers.

The Products We Provide

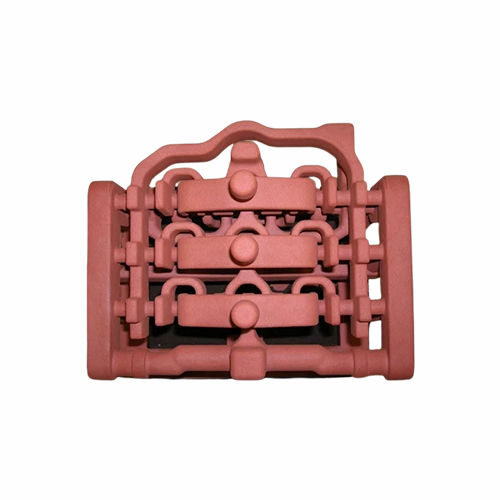

Binders

Tailored resin solutions, emphasizing innovation and operational flexibility for customer requirements.

Read more

Refractory Coatings

Coatings for dipping, spraying, and brushing with optimal performance in various applications.

Read more

Foundry Allied Products

Improve foundry operations using innovative additives, achieving exceptional metallurgical outcomes.

Read more

Refractory

Enhance refractory projects with Novolac resins, known for longevity and ease of handling.

Read more

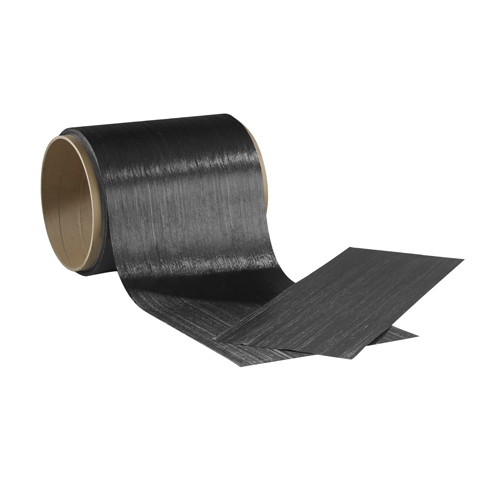

Powder Resin

Optimal performance in refractories, friction, and abrasives with novolac resin.

Read moreWe have 90+ years of experience, in this industry

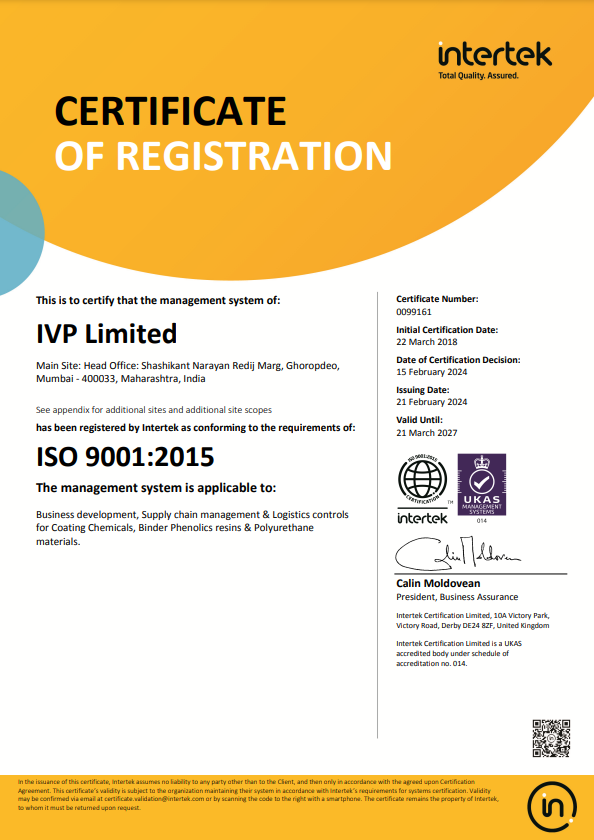

Choose IVP for a seamless blend of tradition and innovation, a relentless dedication to adding value, a customer-centric focus, unparalleled expertise, unwavering quality, sustainability, and a global-local touch. We're not just a chemical provider; we're your steadfast partner in success, committed to delivering tailored solutions that exceed your expectations and contribute to your growth while respecting our rich heritage and embracing modern advancements.

- A leading innovator of value adding chemicals for diverse industrial applications.

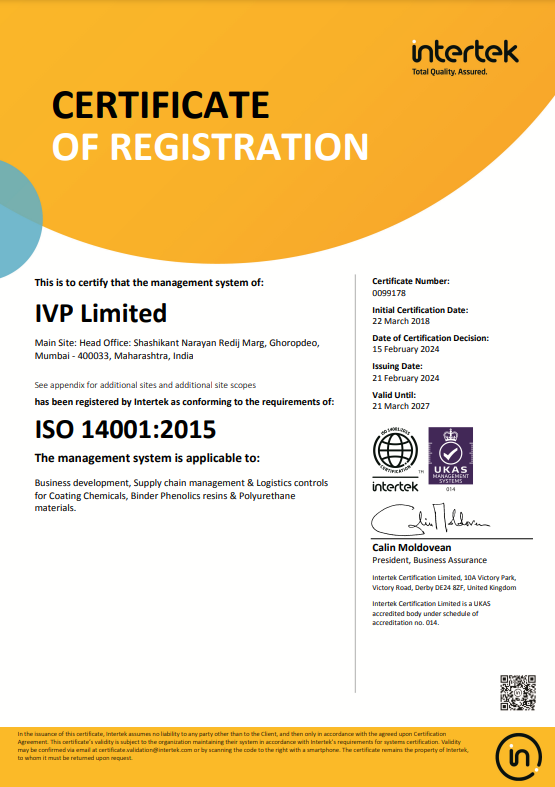

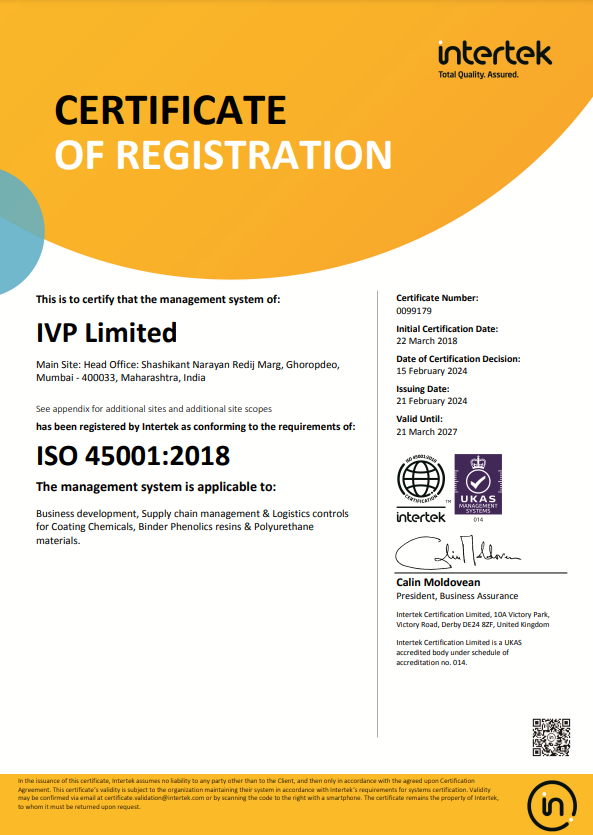

- A responsible manufacturer of superior quality products while maintaining the highest standards of safety, health and environment protection.

- A preferred partner of choice for the customers in the industries we serve.

We have 90+ years of experience, in this industry

Choose IVP for a seamless blend of tradition and innovation, a relentless dedication to adding value, a customer-centric focus, unparalleled expertise, unwavering quality, sustainability, and a global-local touch. We're not just a chemical provider; we're your steadfast partner in success, committed to delivering tailored solutions that exceed your expectations and contribute to your growth while respecting our rich heritage and embracing modern advancements.

- A leading innovator of value adding chemicals for diverse industrial applications.

- A responsible manufacturer of superior quality products while maintaining the highest standards of safety, health and environment protection.

- A preferred partner of choice for the customers in the industries we serve.

00++

Years Legacy

00+

Clients

00+

Products

00+

Happy Employees

Newsroom

Intimation under Reg 30 - Resignation by Senior Management Personnel.

Jun 18, 2019

Announcement under Regulation 30 - Extract of Unaudited financial results for the quarter ended on 30th June, 2023 published in the newspapers.

Jun 18, 2019

Outcome of Board Meeting held on 10th August, 2023.

Jun 18, 2019

.jpg)